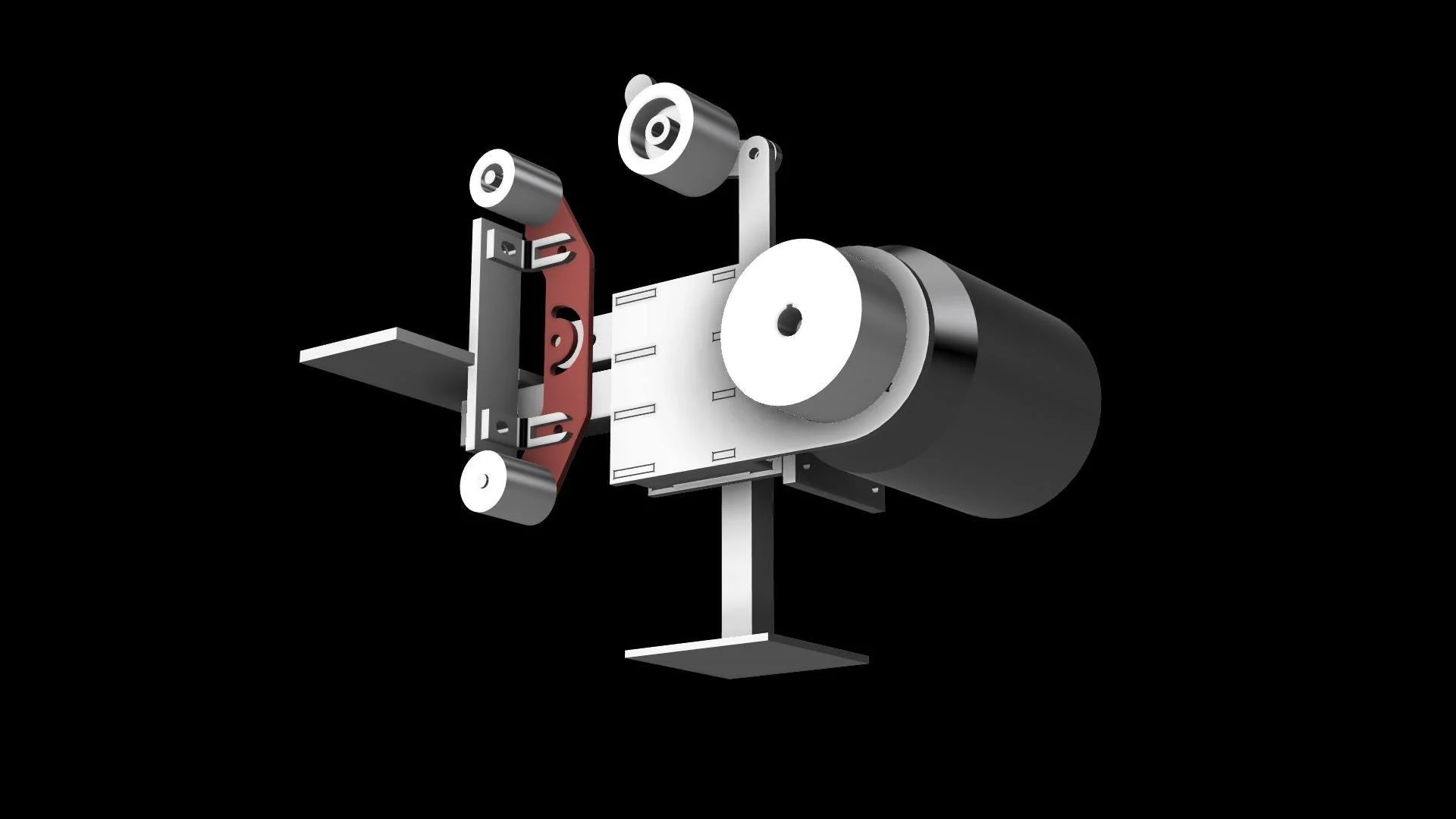

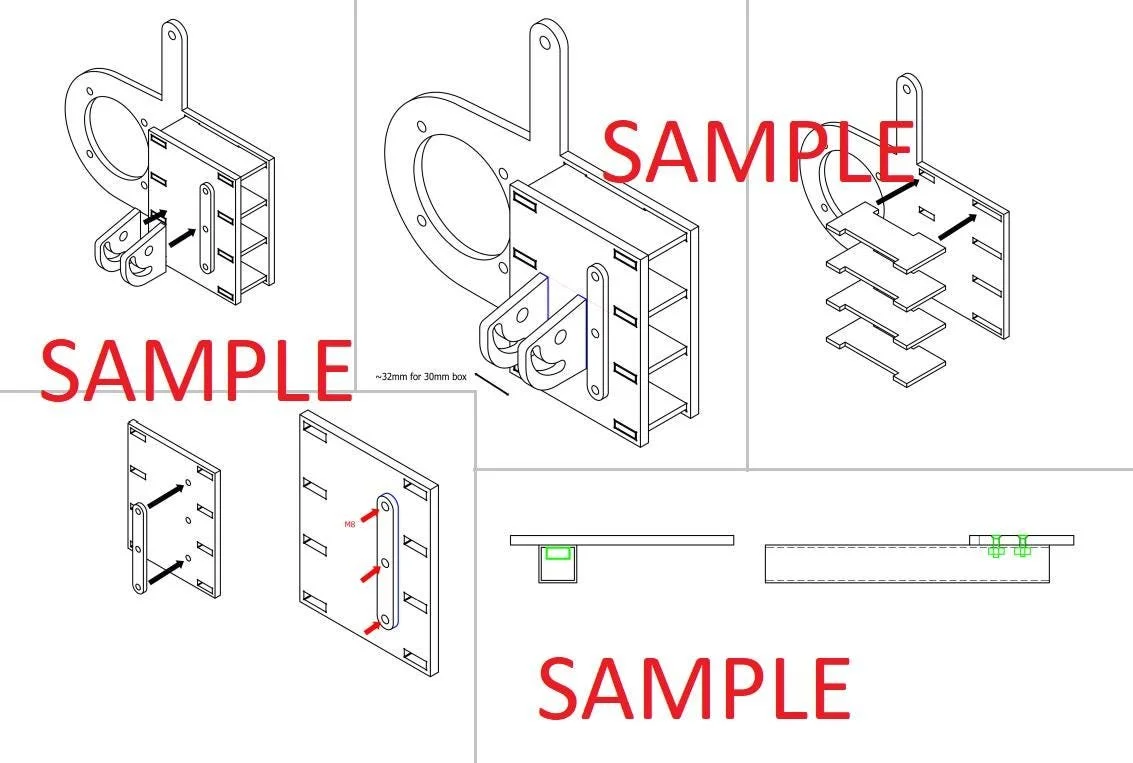

Image 1 of 8

Image 1 of 8

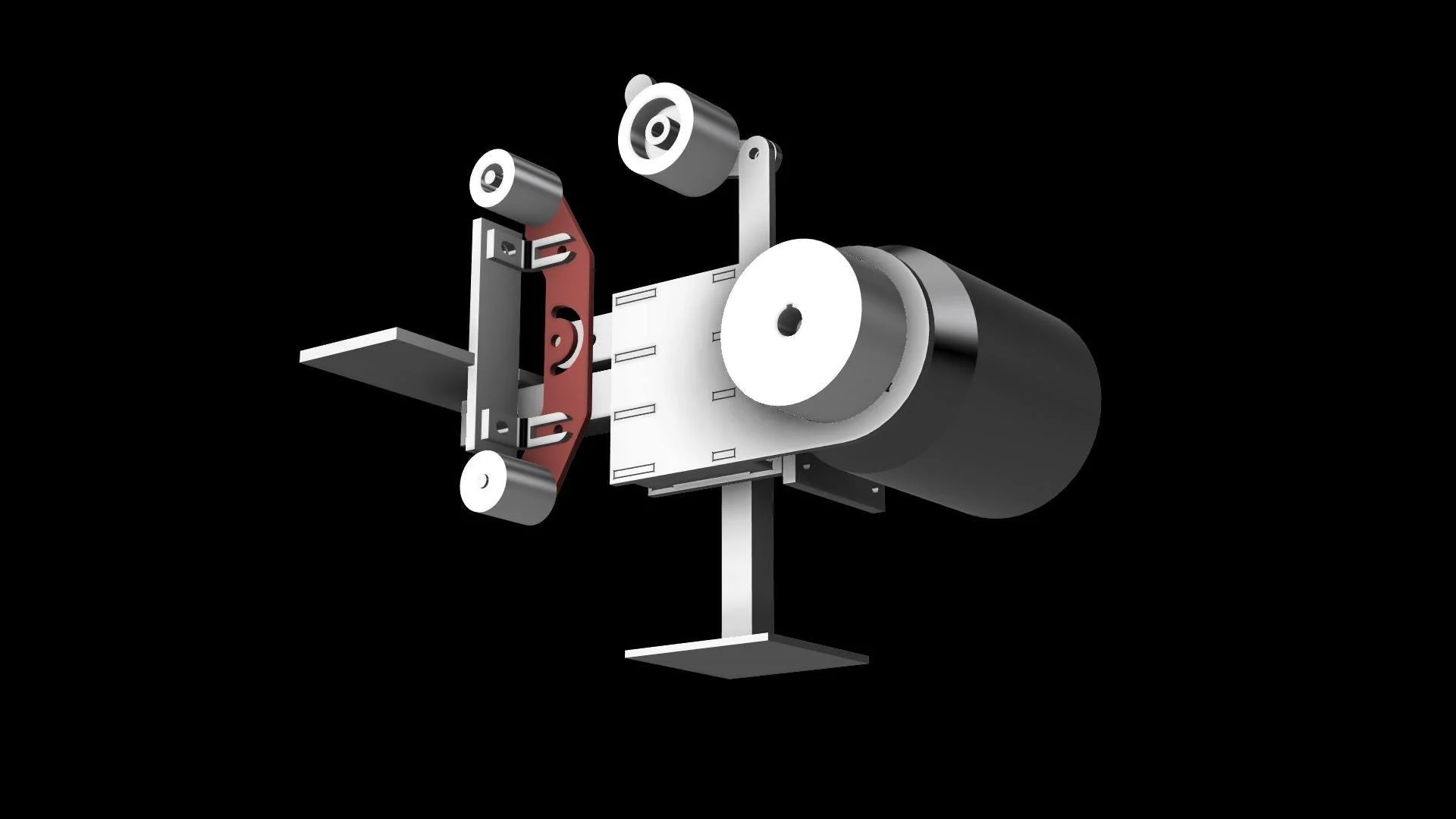

Image 2 of 8

Image 2 of 8

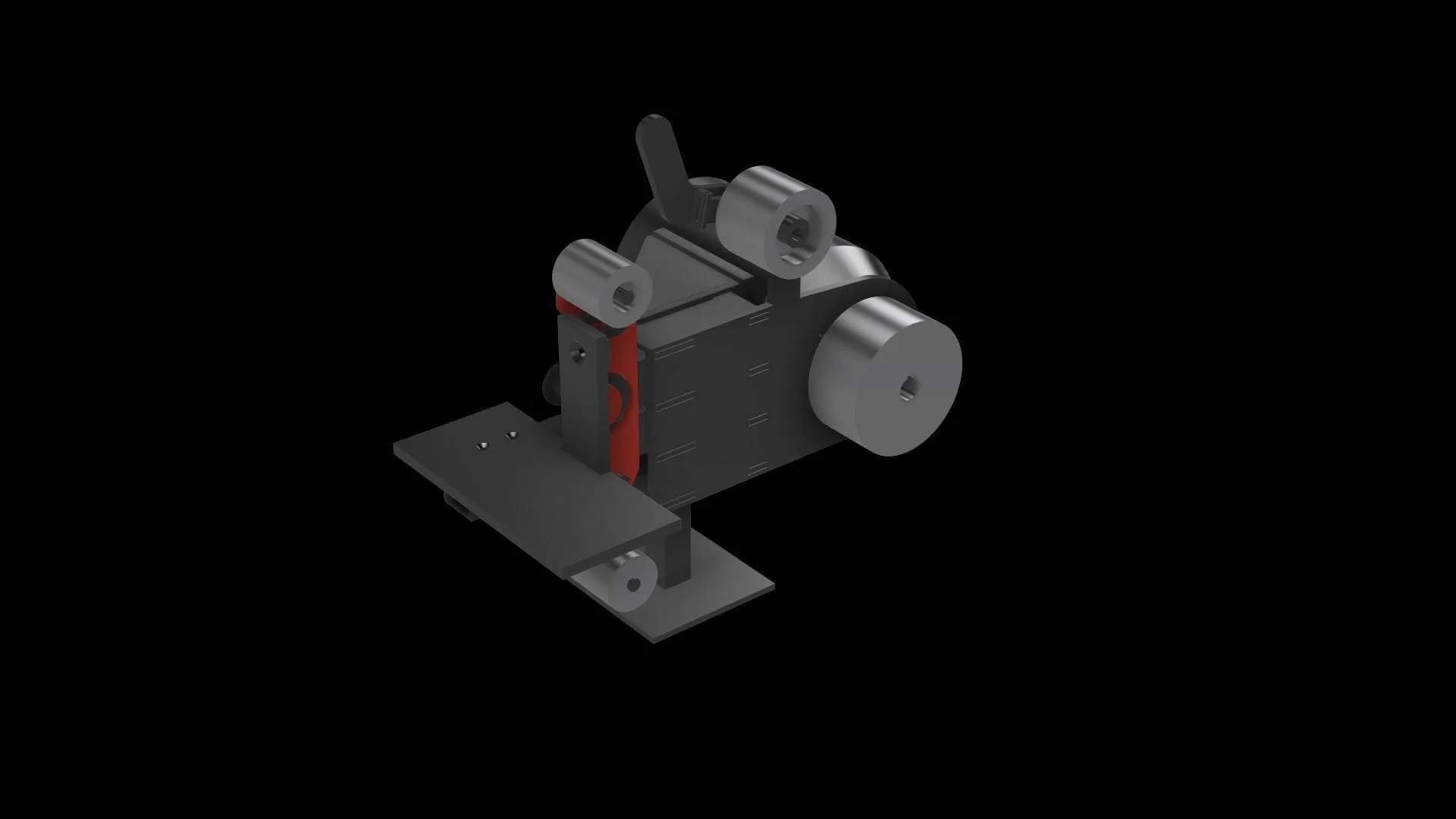

Image 3 of 8

Image 3 of 8

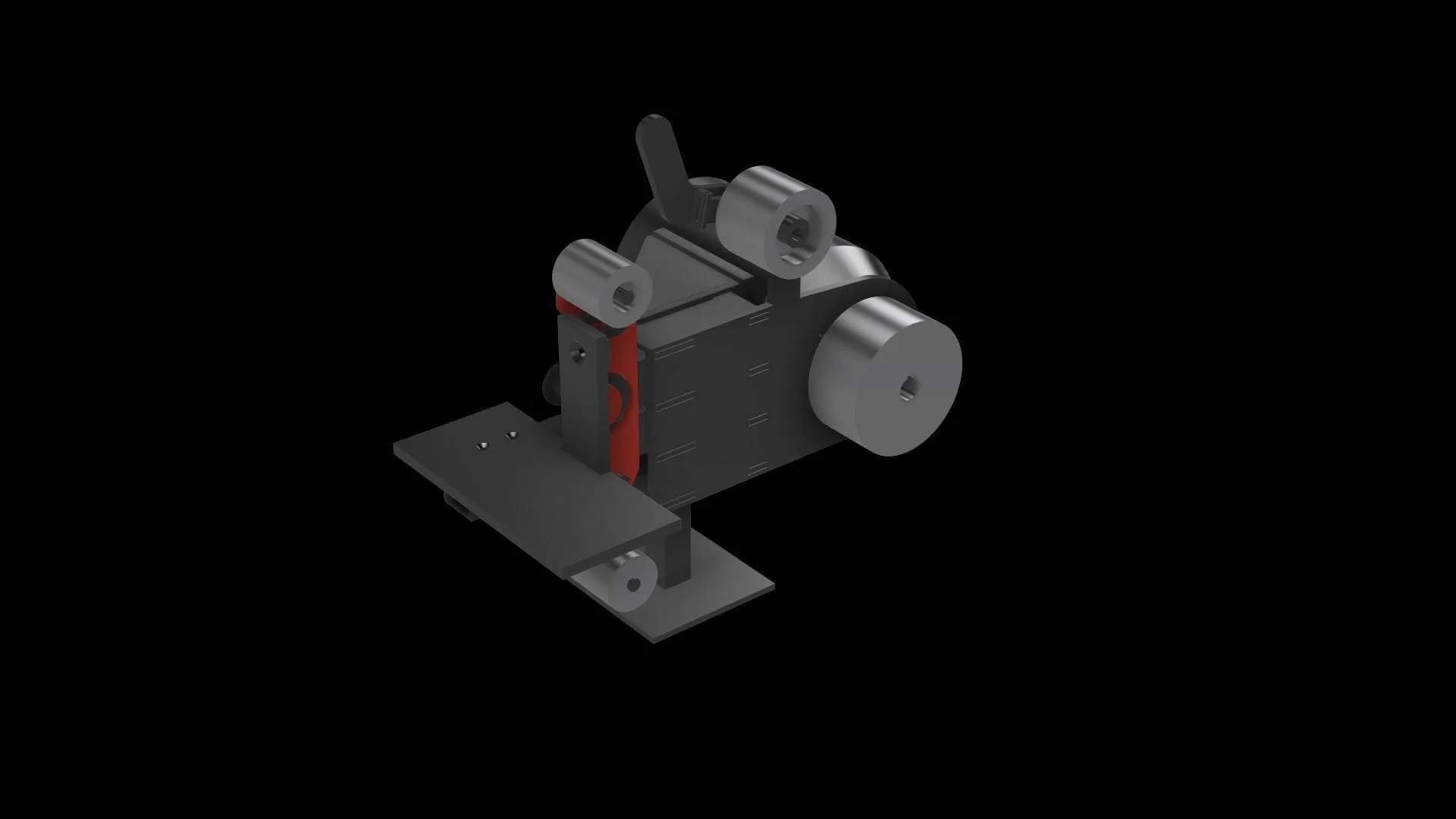

Image 4 of 8

Image 4 of 8

Image 5 of 8

Image 5 of 8

Image 6 of 8

Image 6 of 8

Image 7 of 8

Image 7 of 8

Image 8 of 8

Image 8 of 8

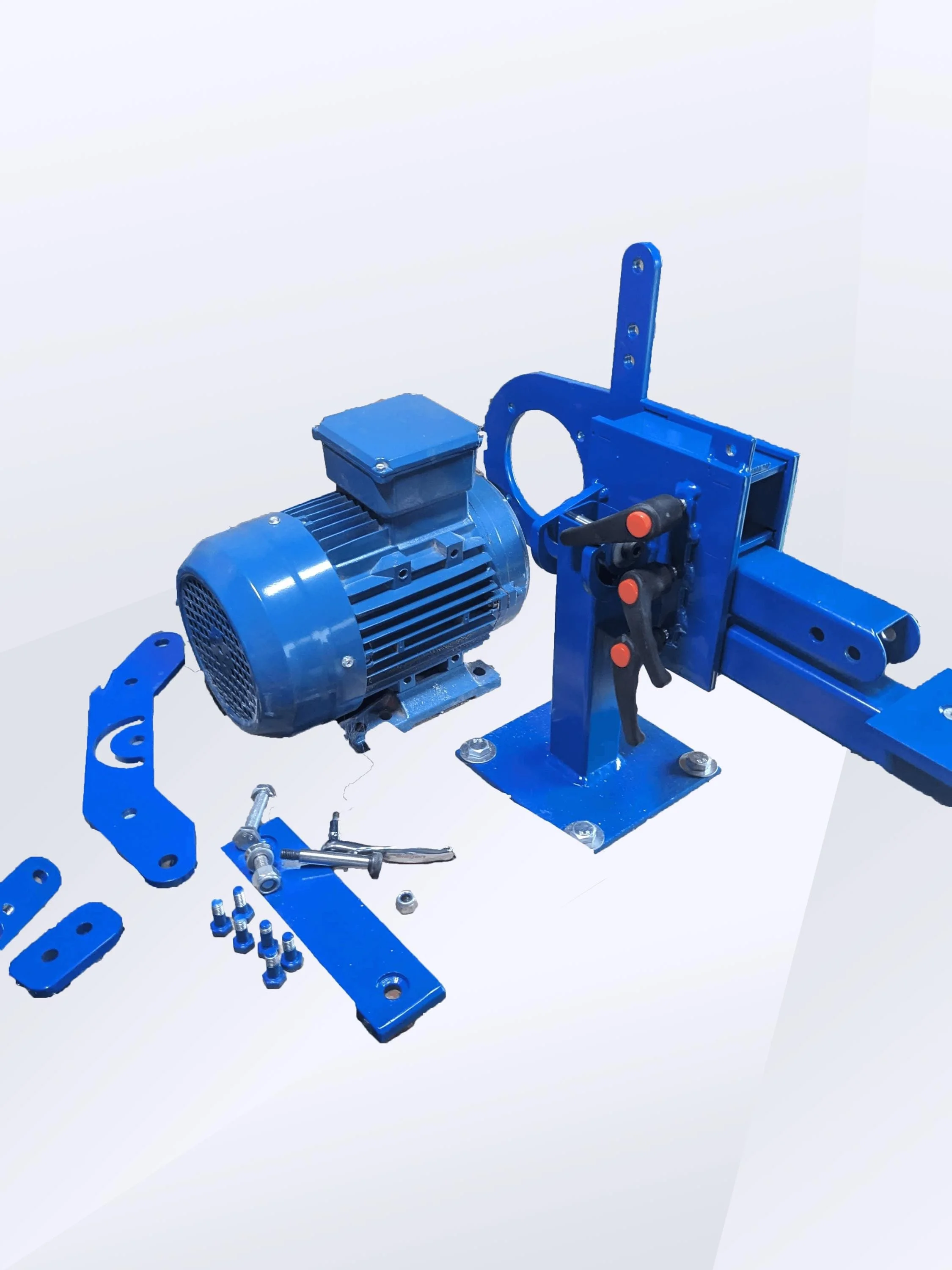

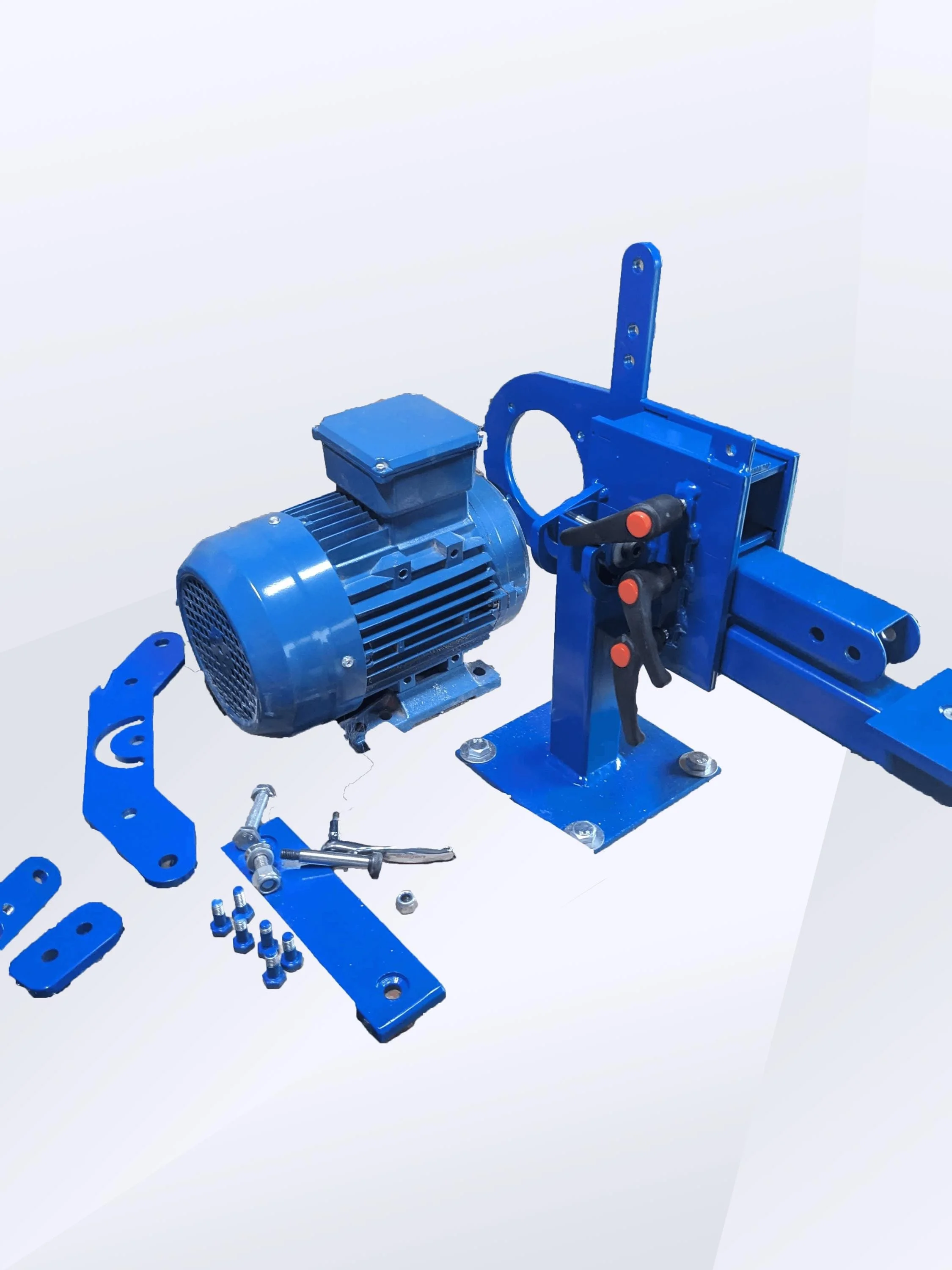

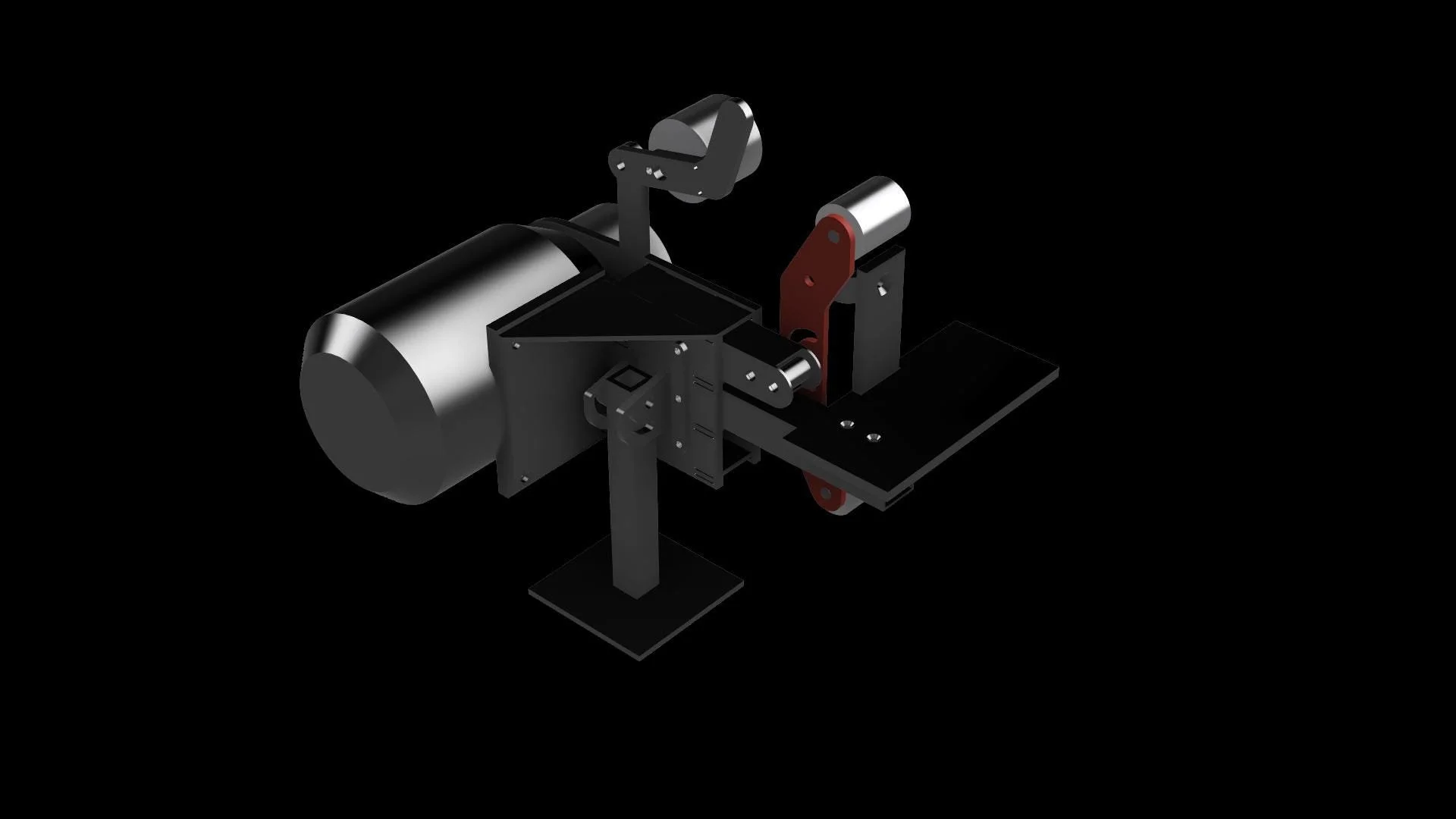

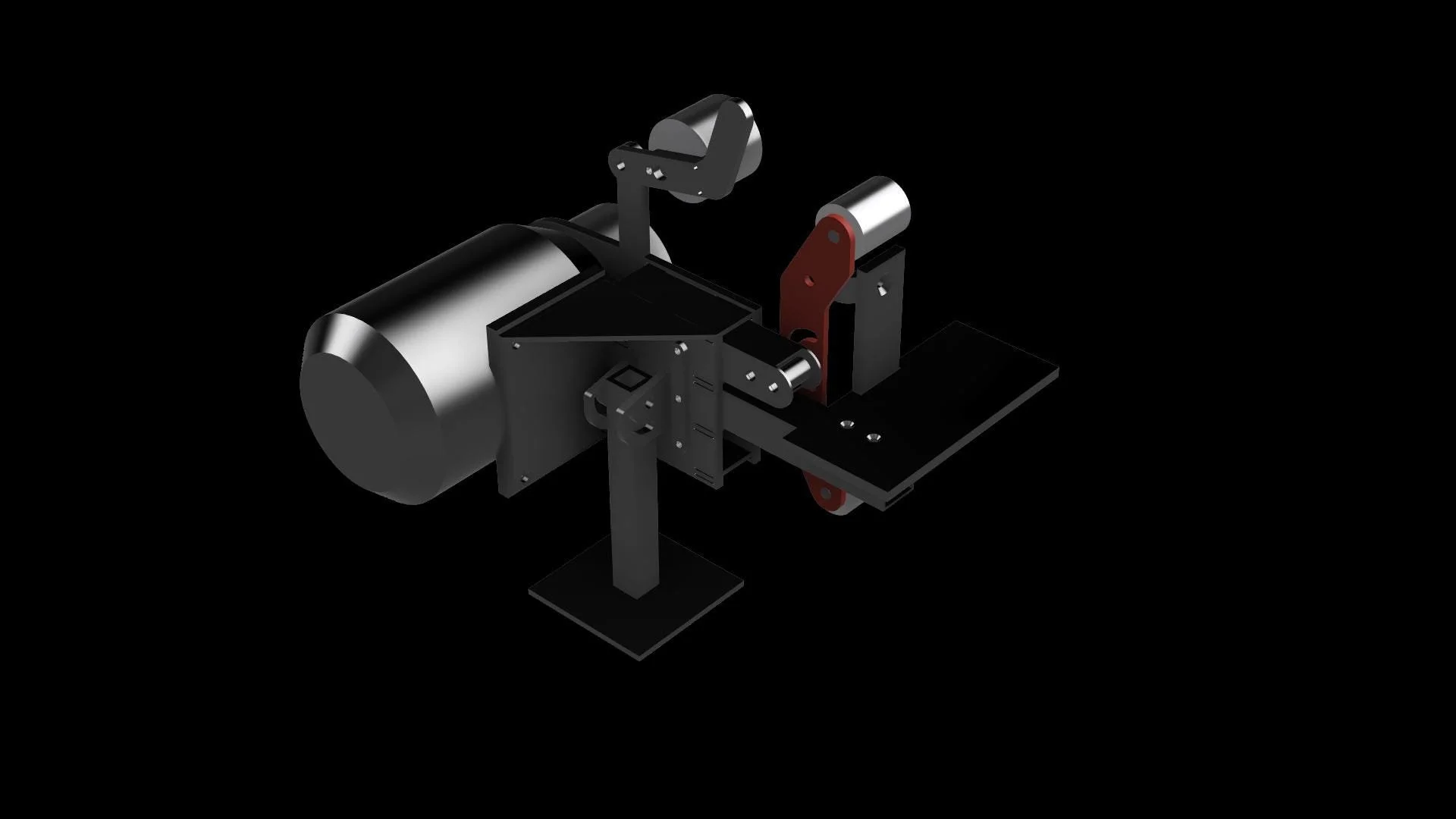

DXF Plans for 2x48 tilting Belt Sander with Assembly Manual, .PDFs, and .DXFs

£12.45

DIGITAL PLANS ONLY

METRIC AND IMPERIAL FILES

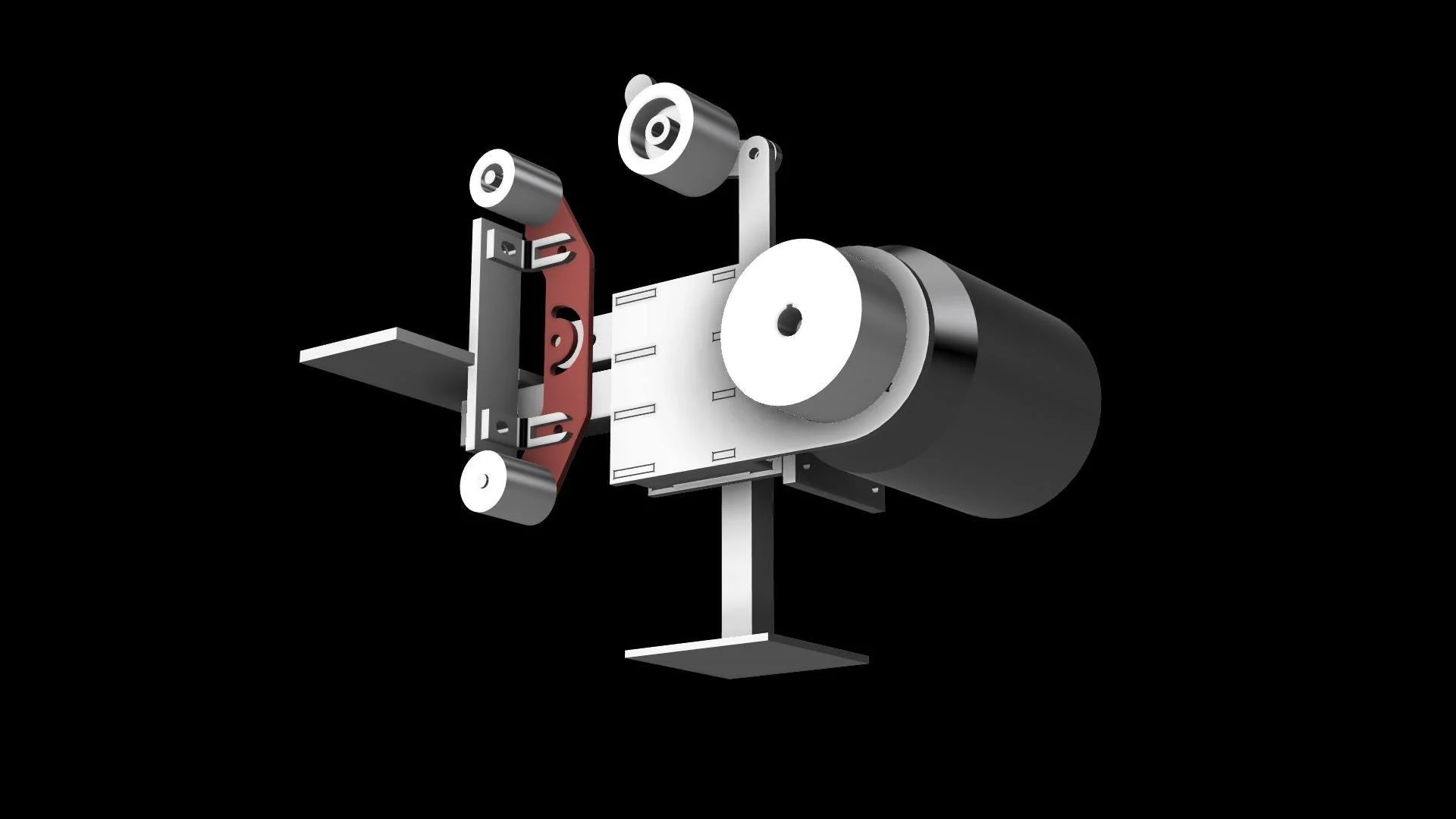

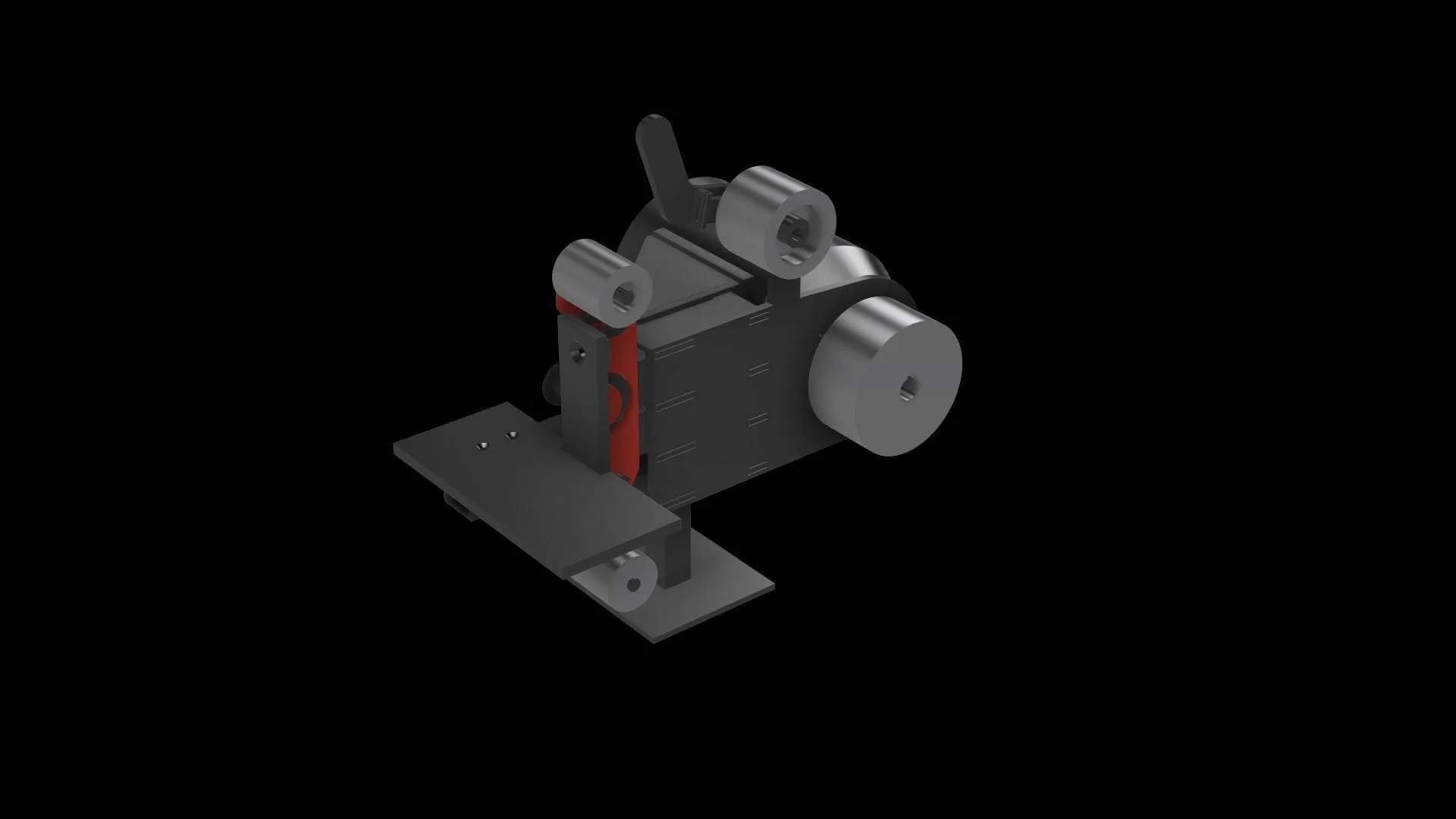

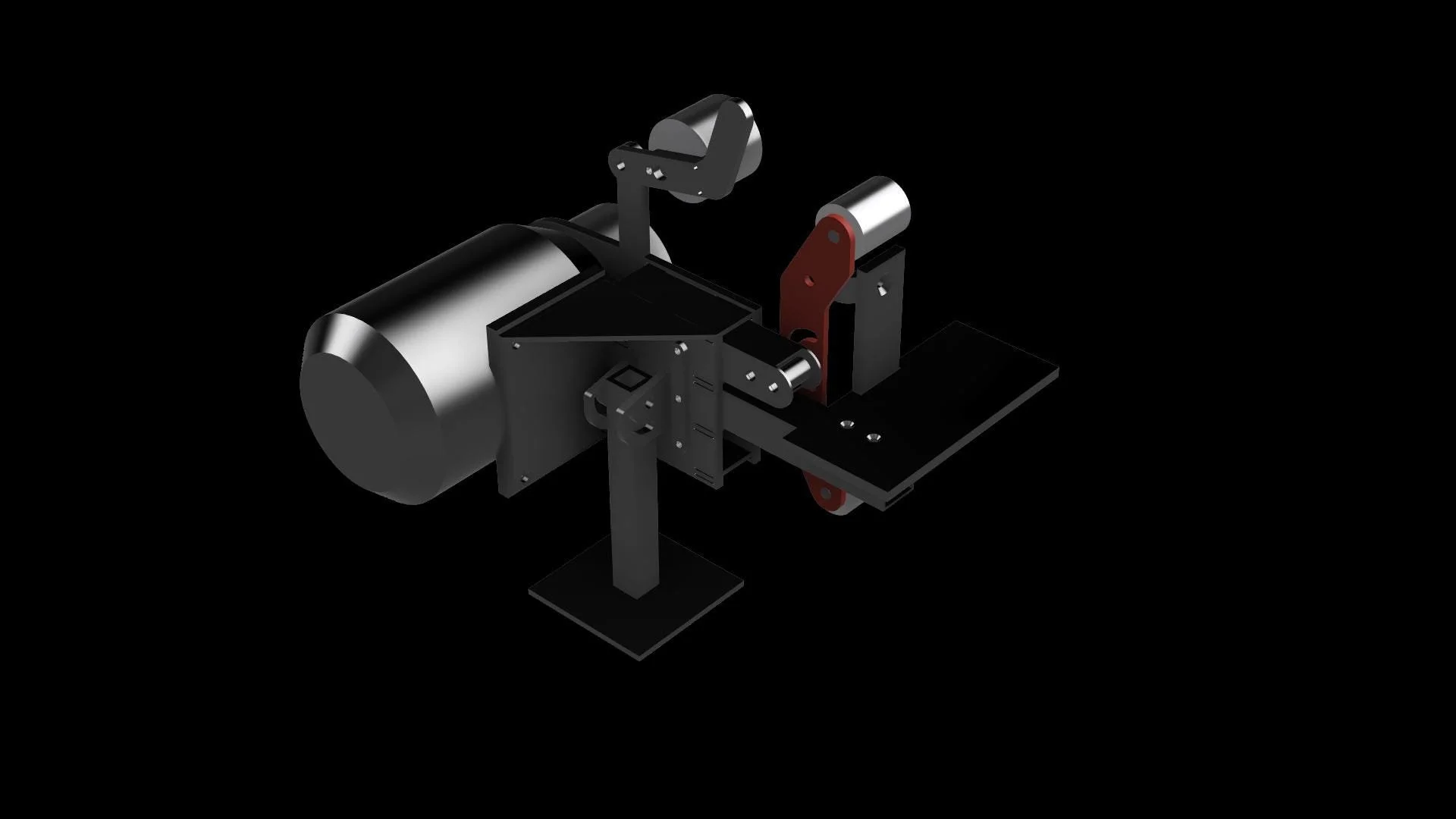

I have been wanting a new belt sander for a while after my old one started stalling and breaking down. After looking around online I realised that I would either have to pay a premium or get one with not many features, so I decided I would build my own.

These are the finalised plans that I have built and tested my own belt sander from: https://youtu.be/_8D2Ayorm0M

After making a few smaller modifications, It was ready to release.

It features:

- Three quick swap attachment slots utilising 40x40 box section

- Angle adjustable platten

- Tilting base and universal rest plate

- Gas strut tensioned adjustable tracking wheel

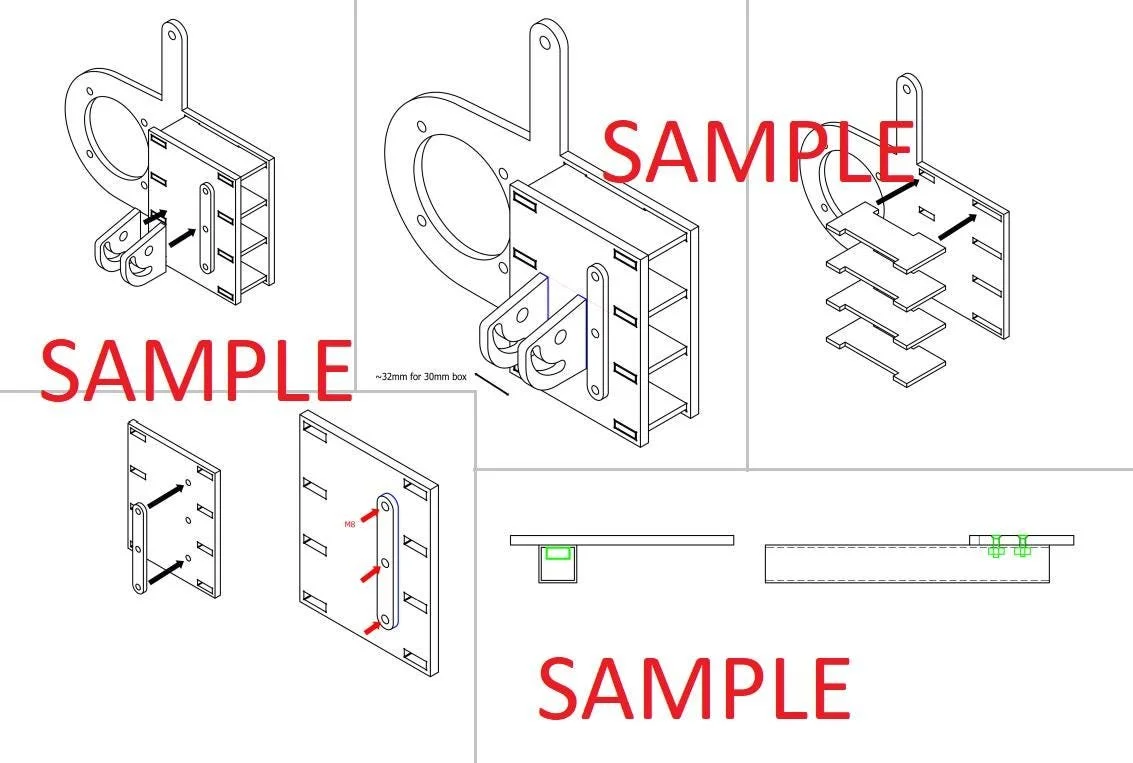

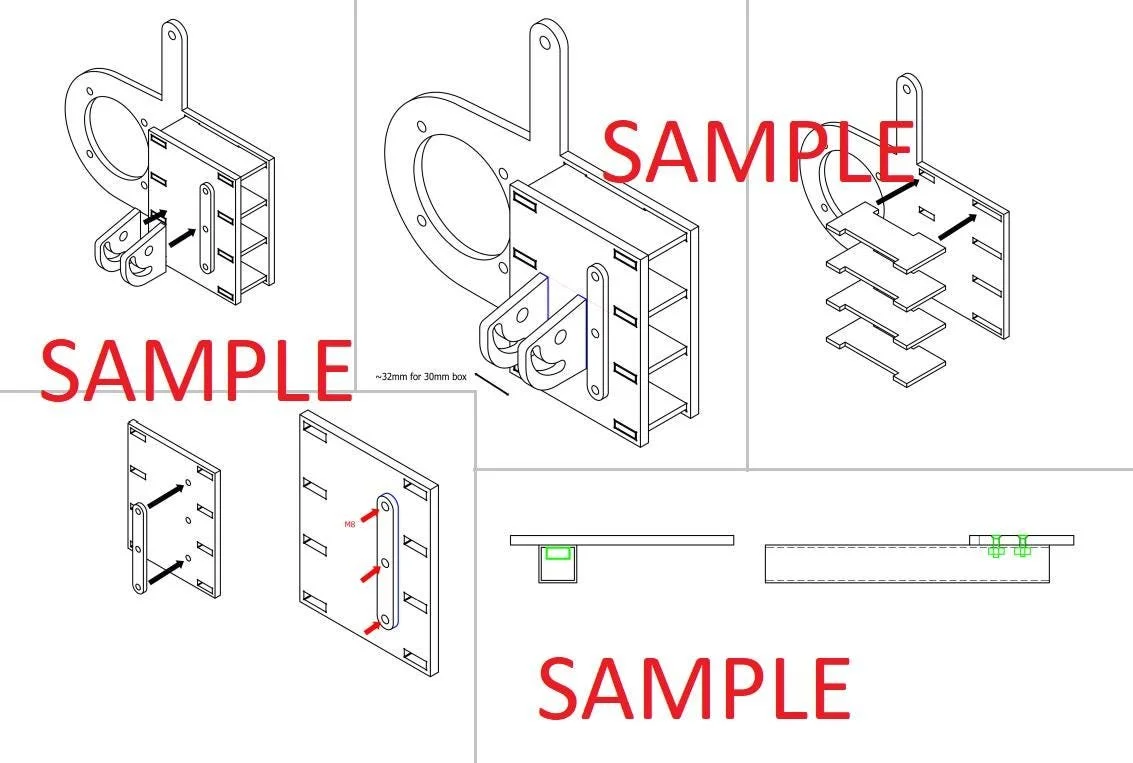

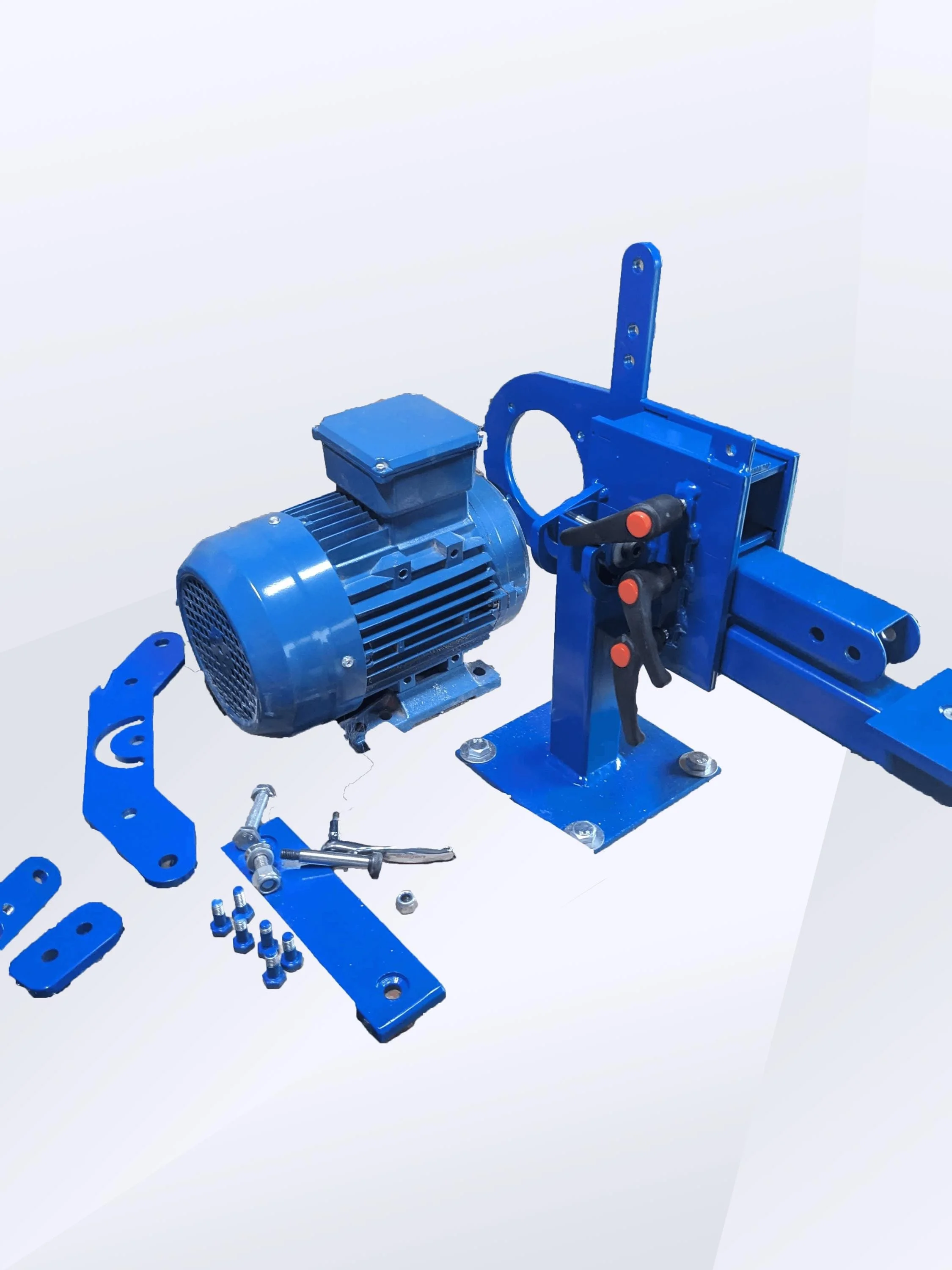

These plans are designed to be built with at minimum a basic understanding of fabrication and access to relevant machinery.

Tool requirements:

- Access to a laser, plasma, or waterjet cutter

- Access to a welder

- Set of hex keys

- Optional access to powder coating or paint.

These project files are for private/personal use only. You may not produce or sell this machine commercially without permission. Do not copy or redistribute these files.

BOM:

- 5mm laser cut steel parts

- 6mm laser cut steel parts

- 8mm laser cut steel parts

- 10mm laser cut steel parts

- 1x 3" tracking wheel

- 1x 5" drive wheel

- 2x 2" idler wheels

- 1.5KW Motor

- 1.5KW VFD

- 800mm 40x40x2mm box section

- 2x M4x10 countersunk bolts

- 1x M4x40 bolt

- 3x M8 handles

- 2x M10x20 countersunk bolts

- 11x M10x20 bolts

- 2x M10x50 bolts

- 2x M10x60 bolts

- 1x shoulder bolt with 10mm shoulder 20mm long

- 1x shoulder bolt with 10mm shoulder 55mm long

- 2x Ground shoulder bolt with 12mm shoulder 60mm long

- 1x Ground shoulder bolt with 12mm shoulder 70mm long

- 1x M4 Nyloc nut

- 3x M10 Nyloc nut

- 3x M12 Nyloc nut

- 4x M10x2mm spacers

- 150N 140mm Gas spring/strut

Tip: Order extra hardware

METRIC AND IMPERIAL FILES

I have been wanting a new belt sander for a while after my old one started stalling and breaking down. After looking around online I realised that I would either have to pay a premium or get one with not many features, so I decided I would build my own.

These are the finalised plans that I have built and tested my own belt sander from: https://youtu.be/_8D2Ayorm0M

After making a few smaller modifications, It was ready to release.

It features:

- Three quick swap attachment slots utilising 40x40 box section

- Angle adjustable platten

- Tilting base and universal rest plate

- Gas strut tensioned adjustable tracking wheel

These plans are designed to be built with at minimum a basic understanding of fabrication and access to relevant machinery.

Tool requirements:

- Access to a laser, plasma, or waterjet cutter

- Access to a welder

- Set of hex keys

- Optional access to powder coating or paint.

These project files are for private/personal use only. You may not produce or sell this machine commercially without permission. Do not copy or redistribute these files.

BOM:

- 5mm laser cut steel parts

- 6mm laser cut steel parts

- 8mm laser cut steel parts

- 10mm laser cut steel parts

- 1x 3" tracking wheel

- 1x 5" drive wheel

- 2x 2" idler wheels

- 1.5KW Motor

- 1.5KW VFD

- 800mm 40x40x2mm box section

- 2x M4x10 countersunk bolts

- 1x M4x40 bolt

- 3x M8 handles

- 2x M10x20 countersunk bolts

- 11x M10x20 bolts

- 2x M10x50 bolts

- 2x M10x60 bolts

- 1x shoulder bolt with 10mm shoulder 20mm long

- 1x shoulder bolt with 10mm shoulder 55mm long

- 2x Ground shoulder bolt with 12mm shoulder 60mm long

- 1x Ground shoulder bolt with 12mm shoulder 70mm long

- 1x M4 Nyloc nut

- 3x M10 Nyloc nut

- 3x M12 Nyloc nut

- 4x M10x2mm spacers

- 150N 140mm Gas spring/strut

Tip: Order extra hardware

DIGITAL PLANS ONLY

METRIC AND IMPERIAL FILES

I have been wanting a new belt sander for a while after my old one started stalling and breaking down. After looking around online I realised that I would either have to pay a premium or get one with not many features, so I decided I would build my own.

These are the finalised plans that I have built and tested my own belt sander from: https://youtu.be/_8D2Ayorm0M

After making a few smaller modifications, It was ready to release.

It features:

- Three quick swap attachment slots utilising 40x40 box section

- Angle adjustable platten

- Tilting base and universal rest plate

- Gas strut tensioned adjustable tracking wheel

These plans are designed to be built with at minimum a basic understanding of fabrication and access to relevant machinery.

Tool requirements:

- Access to a laser, plasma, or waterjet cutter

- Access to a welder

- Set of hex keys

- Optional access to powder coating or paint.

These project files are for private/personal use only. You may not produce or sell this machine commercially without permission. Do not copy or redistribute these files.

BOM:

- 5mm laser cut steel parts

- 6mm laser cut steel parts

- 8mm laser cut steel parts

- 10mm laser cut steel parts

- 1x 3" tracking wheel

- 1x 5" drive wheel

- 2x 2" idler wheels

- 1.5KW Motor

- 1.5KW VFD

- 800mm 40x40x2mm box section

- 2x M4x10 countersunk bolts

- 1x M4x40 bolt

- 3x M8 handles

- 2x M10x20 countersunk bolts

- 11x M10x20 bolts

- 2x M10x50 bolts

- 2x M10x60 bolts

- 1x shoulder bolt with 10mm shoulder 20mm long

- 1x shoulder bolt with 10mm shoulder 55mm long

- 2x Ground shoulder bolt with 12mm shoulder 60mm long

- 1x Ground shoulder bolt with 12mm shoulder 70mm long

- 1x M4 Nyloc nut

- 3x M10 Nyloc nut

- 3x M12 Nyloc nut

- 4x M10x2mm spacers

- 150N 140mm Gas spring/strut

Tip: Order extra hardware

METRIC AND IMPERIAL FILES

I have been wanting a new belt sander for a while after my old one started stalling and breaking down. After looking around online I realised that I would either have to pay a premium or get one with not many features, so I decided I would build my own.

These are the finalised plans that I have built and tested my own belt sander from: https://youtu.be/_8D2Ayorm0M

After making a few smaller modifications, It was ready to release.

It features:

- Three quick swap attachment slots utilising 40x40 box section

- Angle adjustable platten

- Tilting base and universal rest plate

- Gas strut tensioned adjustable tracking wheel

These plans are designed to be built with at minimum a basic understanding of fabrication and access to relevant machinery.

Tool requirements:

- Access to a laser, plasma, or waterjet cutter

- Access to a welder

- Set of hex keys

- Optional access to powder coating or paint.

These project files are for private/personal use only. You may not produce or sell this machine commercially without permission. Do not copy or redistribute these files.

BOM:

- 5mm laser cut steel parts

- 6mm laser cut steel parts

- 8mm laser cut steel parts

- 10mm laser cut steel parts

- 1x 3" tracking wheel

- 1x 5" drive wheel

- 2x 2" idler wheels

- 1.5KW Motor

- 1.5KW VFD

- 800mm 40x40x2mm box section

- 2x M4x10 countersunk bolts

- 1x M4x40 bolt

- 3x M8 handles

- 2x M10x20 countersunk bolts

- 11x M10x20 bolts

- 2x M10x50 bolts

- 2x M10x60 bolts

- 1x shoulder bolt with 10mm shoulder 20mm long

- 1x shoulder bolt with 10mm shoulder 55mm long

- 2x Ground shoulder bolt with 12mm shoulder 60mm long

- 1x Ground shoulder bolt with 12mm shoulder 70mm long

- 1x M4 Nyloc nut

- 3x M10 Nyloc nut

- 3x M12 Nyloc nut

- 4x M10x2mm spacers

- 150N 140mm Gas spring/strut

Tip: Order extra hardware